Ultimaker Factor 4

$49,450.00 Inc GST

UltiMaker Factor 4 is the latest in industrial-grade 3D printers from ultiMaker. It’s designed to take manufacturing to new levels of efficiency and reliability. It is engineered for the development and production of process-critical tools and components. Built on over a decade of dedication to openness and accessibility, this machine supports one of the widest material portfolios on the market for a variety of applications, including end use parts, functional prototyping, manufacturing tools, and small batch manufacturing of auxiliary components and spares.

The UltiMaker Factor 4 has been thoroughly tested to ensure it achieves a print completion success rate of over 95% (print completion success rate tested using UltiMaker PLA, Tough PLA, PETG, PET CF, and PPS CF). This is made possible by its PEI-coated flexible built plate, allowing for excellent adhesion. It’s automatic inductive bed leveling ensures a perfect first layer for every print.

Introducing the Ultimaker Factor 4 – 3D Printer

Industrial grade performance

Engineered for the development and production of process-critical tools and components. With support for engineering materials, direct drive dual extrusion, onboard print quality reporting (license subscription required), temperature-controlled build volume 330 x 240 x300 mm, and other innovative features, it delivers high levels of predictability and minimal variance - achieving a dimensional accuracy of ± 0.2 mm + ± 0.2% of feature nominal length over the full build plate.

Built for the factory floor

Constructed from robust steel, aluminium, and glass, Factor 4 is built for the factory floor. The printer features a triple-insulated build volume, closed loop and direct drive dual extrusion, automatic inductive bed levelling, and a PEI-coated flexible build plate, ensuring consistent production output, even on complex and challenging designs. The integrated, low moisture material handling system is climate controlled, with humidity levels kept below 15%, and holds up to six spools of filaments in their prime condition.

Direct drive high temperature printing

Direct drive high temperature printing

UltiMaker Factor 4 raises the temperature up to 340 °C using the UltiMaker HT Print Core. This means that you can now 3D print higher temperature-resistant and durable materials like UltiMaker PPS-CF. UltiMaker PPS-CF is a semi-crystalline thermoplastic material, reinforced with carbon fiber. The material has a temperature resistance greater than 230°C, is flame retardant, and highly chemical resistant. It provides a high-performing alternative to steel or aluminium for less-demanding parts, enabling users to unlock new industrial applications.

Redesigned gantry and direct drive extrusion

The combination of the all-new H-bridge gantry and direct drive extrusion print head allows high-speed movement and positional accuracy. This results in best-in-class dual material printing speeds so that you can quickly create the flexible or strong parts you need.

Temperature controlled build volume

Temperature controlled build volume

The UltiMaker Factor 4's spacious triple insulated build chamber allows you to utilise every millimeter of the build plate with direct drive dual extrusion. This means that you can now 3D print higher temperature resistant and durable materials with more confidence.

The temperature within the fully enclosed build volume is also controlled up to 70 °C, with a heated bed up to 120 °C, ensuring optimal material-specific processing conditions and consistent part quality wherever the 3D printer is located.

Hassle-free material handling

A new, integrated, automatic material handling system reliably manages your filament spools so you don’t have to. The internal chamber is kept at less than 15 % RH, so you can keep up to 6 kilograms of filament in perfect condition for back-to-back print jobs. It features an automatic material change capability, which seamlessly switches between filament spools, eliminating downtime and ensuring uninterrupted printing, for those printing a single part that may require several days or multiple spools.

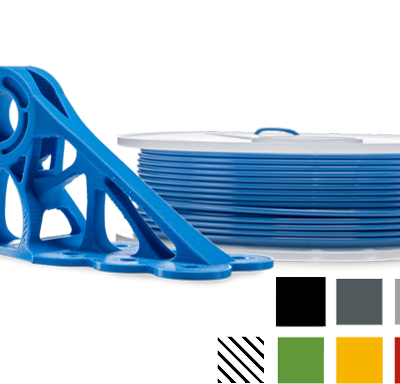

Advanced Ultimaker materials and limitless third-party filament

Built on over a decade of dedication to openness and accessibility, the Factor 4 will support one of the widest material portfolios on the market for a variety of applications, including end use parts, functional prototyping, manufacturing tools, and small batch manufacturing of auxiliary components and spares. Try the new Ultimaker PPS-CF to create super strong advanced parts.

Built on over a decade of dedication to openness and accessibility, the Factor 4 will support one of the widest material portfolios on the market for a variety of applications, including end use parts, functional prototyping, manufacturing tools, and small batch manufacturing of auxiliary components and spares. Try the new Ultimaker PPS-CF to create super strong advanced parts.

Factor 4 expands the range of high performance, industrial-grade materials, from flexible materials to high-temperature composites. 3D print flexible materials from TPU 95A down to Shore 70A (TPU 70A) reliably with Factor 4, enabling you to create flexible parts like gaskets, seals, and shock absorbers.

From colourful ultimaker PLA to flexible TPU, get high-quality results across all Ultimaker build materials. And with an open filament system, choose almost any third-party 3D printing filament for unlimited choice and innovation. Ultimaker offers the widest material choice on the market. With an open filament system, you can always find the right material properties for your application – from good aesthetics to wear resistance or flexibility. Print with a wide range of engineering materials and easy-to-remove support. Ultimaker’s dual-extrusion technology enables designers and engineers to create complex geometries, for applications from prototyping to manufacturing aids and end-use parts.

Modularity and Support

Modularity and Support

UltiMaker Factor 4 was designed to be modular. This means less production downtime in the event that a part of the printer needs servicing. Faulty component can be quickly swapped out for a functional one to get you up and running again as quickly as possible. Wherever you are in Australia, ultimaker reseller 3D Stem support is close by. We offer professional installation, training, and maintenance. Pending on your location.

Software ready for Industry 4.0

Trusted by millions of users across 14 languages, Ultimaker Cura integrates with any workflow through ultimaker Marketplace plugins. Then scale production and digital distribution with Ultimaker Cloud.

Cloud 3D printing built in

Leverage the full power of Ultimaker Cura. Slice with your choice of extensively tested Ultimaker material profiles, or tweak over 400 advanced settings. Then click "print via the cloud" whether you're at the office or not. Ultimaker Marketplace lets you customize your slicing experience with plugins (including CAD integration) for a simpler 3D printing workflow. At home or in the office, easily send print jobs to the Ultimaker Factor 4 Via Wi-Fi or Ethernet, cloud 3D printing allows remote file transfer with added security from anywhere in the world.

Features

7-inch interactive touchscreen - UltiMaker Factor 4's larger 7-inch interactive touchscreen shows more real-time process data.

Emergency stop button - An Emergency STOP button ensures safe operation, should there be a need to immediately halt printing.

Onboard structural integrity validation - Sensors in the print head, build chamber, and material loading system, allow for in-depth print process reporting (license subscription required) to verify and validate part quality.

Integrated HEPA filter - Independently tested to remove up to 95% of ultrafine particles to increase air quality peace of mind. The fully enclosed build chamber also boosts print quality.

Regular updates - Regular updates ensure that your Factor 4 will evolve over time – far beyond the estimated 12 to 18 months it will take to achieve return on investment. With dual onboard processors, there is plenty of computing headroom for planned and even unplanned future updates.

Bundles add ons & spare parts

The Ultimaker Factor 4 has two separate bundles a "printer station" bundle and a "all in" bundle including the printer station, PPS-CF and HT print core.

Ultimaker PPS-CF - PPS CF 3D printing material is reinforced with high-quality carbon fiber. This provides outstanding tensile strength and stiffness to your 3D printed parts accompanied with exceptional part performance. Built to withstand the rigors of real-world applications, PPS CF (polyphenylene sulfide, reinforced with 10% carbon fiber) boasts high chemical resistance, heat resistance, and dimensional stability. Now you can be more confident than ever that your industrial prototypes or functional end-use parts will stand the test of time. UltiMaker PPS CF unlocks a new category of 3D printing applications. Not only is it highly temperature resistant (with an HDT B of over 230 °C after printing), it also resists solvent below 200 °C and is flame retardant – intrinsically meeting the UL94 V0 standard. UltiMaker PPS CF is a material developed with precision and attention to detail. A low filament diameter variance across the entire spool ensures consistent flow and exceptional print quality. Combined with the latest technology of UltiMaker Factor 4 and Cura's easy slicing workflow, it offers hassle-free printing with a dimensional accuracy of ± 0.2 mm + ± 0.2% of feature nominal length, and a smooth surface finish. This makes it ideal for small batches of auxiliary components and spare parts that demand reliable and repeatable results. UltiMaker PPS CF provides a high-performing alternative to steel or aluminum for less-demanding parts. Its properties also allow it to replace PEEK – offering a more cost-effective, more reliable, and easier 3D printing experience.

HT print core 0.6mm

Specifications

Technology - Fused deposition modeling (FDM)

Extrusion system - Dual-extrusion, direct drive print head with unique auto-nozzle lifting system and swappable print cores

Build volume - Single material printing: 330 x 240 x 300 mm (13 x 9.4 x 11.8 in) Dual material printing: 330 x 240 x 300 mm (13 x 9.4 x 11.8 in)

Filament diameter - 2.85 mm

Print profiles availability - 14+ UltiMaker materials 250+ UltiMaker Marketplace materials

Dimensional accuracy - ± 0.2 mm ± 0.2 % feature nominal length For detailed conditions visit ultimaker.com/factor4

XYZ resolution - 6.25, 7.8, 2.5 micron

Homing sensor - Optical

Build plate - PEI-coated flexible build plate

Build plate temperature - Up to 120 °C (248 °F)

Build volume temperature - Actively controlled up to 70 °C(158 °F) with nozzle plane temperature uniformity within:

± 3 °C (5.4 °F) for temperatures < 50 °C (122 °F)

± 5 °C (9 °F) for temperatures < 70 °C (158 °F)

Extrusion flow - Closed loop flow compensation

Max. extrusion temperature - 280 °C (536 °F): Print core AA, BB, DD, 300 °C (572 °F): Print core CC, 340 °C (644 °F): Print core HT

Closed loop fans - Air filtering fan, air recirculation fans, print cooling fans, print core cooling fan

Compatible print cores - Print core AA (0.25 mm, 0.4 mm, 0.8 mm) Print core BB (0.4 mm, 0.8 mm) Print core CC (0.4 mm, 0.6 mm) Print core DD (0.4 mm) – available in selected regions Print core HT (0.6 mm)

Material handling system capacity - 6 bays with NFC recognition (max. 1 kg spool size)

Material handling system humidity control - Average relative humidity < 15 % in all operational conditions

Microparticulate filtration system - HEPA H13

Emission rate (UFP & VOC) - UltiMaker filaments below limits listed in UL-2904

Monitoring - HDR (high dynamic range) 1920 x 1080 px HD camera

Display - 7-inch touchscreen (resolution 1024 x 600 px)

Connectivity - Wi-Fi 2.4 & 5 GHz: IEEE 802.11a/b/g/n/ac LAN: Gigabit Ethernet USB: 2.0

System on module - NXP i.MX8 Mini Quad (4 x 1.8 GHz), ARM Cortex-A53, 2 GB LPDDR 4 16 GB eMMC

Real time controller - i.MX RT1064, Arm Cortex-M7 600 MHz, 1 MB SRAM

Power requirement - 100 – 240 V AC, 50 – 60 Hz max., 6A

Dimensions - 695 x 605 x 1287 mm (27.5 x 24 x 51 in)

Weight - 120 kg (265 lbs)

Shipping dimensions - 760 x 800 x 1587 mm (30 x 31.5 x 62.5 in)

Shipping weight - 137 kg (309 lbs)

Operating sound - < 50 dBA in operation

Operating environment - Operating: Temperature: 18 °C – 30 ºC (64 – 86 °F), humidity: 30 – 70% RH Storage: Temperature: 5 °C – 40 ºC (41 – 104 °F), humidity: 20 – 90% RH

Print job preparation - UltiMaker Cura 5.7.1 or newer

Print job management - UltiMaker Digital Factory

File types supported - UltiMaker Cura: STL, OBJ, 3MF Printable formats: G, GCODE, UFP, STEP

System requirement - Windows 7 (64-bit) Mac OS X 10.12 OpenGL 2.1 4 GB RAM (8 GB recommended)

Print process reporting - Supported

Security - Active firewall PIN code settings protection

Warranty period - 12 months limited warranty

Certifications - For a detailed list of certifications visit factor 4

Safety features - Red stop button immediately stwww.ultimaker.com/factor4ops motion and heat sources, Open door sensor pauses motion and extrusion

Additional information

| Weight | 20 kg |

|---|---|

| Brand | UltiMaker |